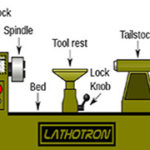

Remove chips, dirt, etc. from the spindle and mounting plate. Nicks, burrs, etc. should be removed by careful honing either the spindle or mounting plate. Install as follows:

THREADED SPINDLES: Screw mounting plate tight against the shoulder of the spindle.